It makes perfect financial sense to want to patch a hole in your tire rather than have to replace it. The patching process for a big hole in the tire is exactly the same as any repairable hole.

The first thing to consider is that any hole more than 6 mm in diameter cannot be patched. If the hole in your tire is bigger than this, then you’re going to need to replace the tire instead.

It can be quite difficult to visualize how big a ¼ inch or 6 mm actually is. The easiest way to compare it to something you are likely to have in your pocket is to search for a dime. A dimes circumference is 18 mm, so if the hole is bigger than a third of this size, it is too big to be repaired.

Also, if the hole is jagged and ripped and less circular, this could cause problems in trying to do an effective repair.

Finally, any hole in the sidewall or shoulder of your tire, however big, cannot be patched as it is dangerous here and risks a blowout.

Here is a 14 step guide on how a car shop will patch a big hole in your tire.

I have also included an extremely well put together and thorough video on what to do if you are more visual and bored of reading!

Tire Shop Big Hole Patch Repair Process

- Mark the tire hole area with a cross on the inside and outside.

- Remove the nail or screw from the tire. You can usually do this from the outside of the tire with pliers.

- Push a reaming tool in the hole to find out the angle of the hole. If more than 25 degrees, you’ll need a 2-step repair – mentioned further on.

- Apply the pre-buff solution to clean the area of silicone that may be left over from the manufacturing process. The patch won’t take unless this is cleaned.

- Drill into the puncture area starting from the inside of the tire at least three times. Do the same on the outside of the tire. Clean away any rubber residue.

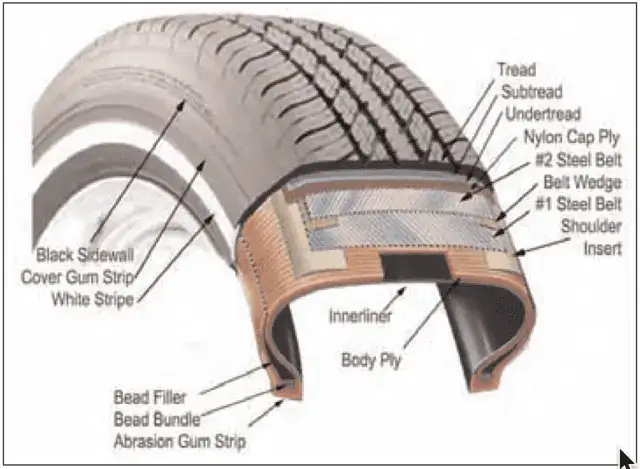

- Buff the inside of the tire hole area very gently, but don’t t expose the body plies.

- Ensure you get the gray color rubber off, as you need to get down to the original black rubber. If you buff too much, the tire will be ruined, so go easy here.

- Cover the holes surrounding the area with cement using the probe or reaming tool you used to check the tire angle. Add cement to the buffed area.

- Push the combi patch plug through the hole from the inside of the tire and pull the stem through the hole using pliers.

- Use a roller to smooth out the patch inside the tire then remove the patch film.

- Use liner sealer on the patched area – which is a synthetic rubber.

- Vacuum out any debris.

- Trim off the excess rubber stem on the outside of the tire, so it is flush with the tread. DO NOT have it pilled tight with pliers when doing this.

- If your patch is self-vulcanizing, it will melt into the tire’s rubber when heated up after you start driving.

Patching a large hole in a tire correctly will take about 30 minutes.

Location On The Tire Of A Big Hole

It is quite surprising when you find out for the first time how little of a tire can actually be patched. This is due to the tire’s construction being different on separate parts of its structure.

The sidewalls and shoulders of a tire have different functions than the tread. Their two jobs are to support the weight of the tire but they also need to flex so that you get a smooth ride when you drive over a pothole or a bump.

Because of the need for flexibility, this part of the tire doesn’t have any reinforced steel belts and it is more vulnerable to blowing out than the tread area if damaged.

However, tempting it may be to patch a sidewall don’t do it. It’s extremely dangerous and not recommended by any tire manufacturer. No reputable car shop will patch a hole here for you irrespective of how big or small it is.

The Angle of The Hole

There are two types of tire patches a one-piece and two-piece. The hole angle dictates the patch used on your tire’s large hole. If the hole is at a 25-degree angle or more to the tire surface a two-piece repair will be needed.

To work out the angle either you or the tire shop can use a reaming tool to see what angle the whole has gone through to the inside of the tire.

In reality, it matters very little to you the driver which one is used although it could cause a little more concern if the hole is close to 6 mm with an angled entry to the tire as opposed to one that has gone straight in at 90 degrees.

A tire shop would advise if they are happy to do a repair on a tire that has an entry hole at an angle.

General Tire Condition

Even if the hole is less than 6 mm wide and the tire is in poor condition, you may feel now is the time to replace it rather than repair the hole.

Common signs that the tire is getting towards the end of its life is low tread. A tire becomes illegal at 2/32 inches of tread, so if your tire is getting close to this, it may be time to replace it.

Also, look for signs of cracking on the side wall and the tire looking less pristine black than it was when you first bought it. The graying and cracking are due to UV sunlight drying out the chemicals used to keep the tire supple when it left the factory.

Previous Repairs On the Tire

Even if the hole is within the repairable zone on a tire tread, if it has been repaired before it may not be patchable a second time however big or small the hole is

Also, if the tire has been patched before and the second hole is within 16 inches of it on the circumference, a tire shop will not repair it.

It is deemed that the structure of the tire would be undermined if a second repair was conducted this closer to the first.

![How Fast Can You Drive On A Patched Tire? [ANSWERED] tire-patch-repair](https://carzaza.com/wp-content/uploads/2023/12/tire-patch-repair-300x150.png)

![Are Tire Patches Permanent? [ANSWERED] tire-patch-tire-shop](https://carzaza.com/wp-content/uploads/2023/12/tire-patch-tire-shop-300x224.png)

![How Many Times Can You Patch A Tire? [Answered] inflating-tire-on-balancing-machine](https://carzaza.com/wp-content/uploads/2023/12/inflating-tire-on-balancing-machine-300x150.png)

![Average Cost Of A Tire Patch [Shop and at Home] tire-patched](https://carzaza.com/wp-content/uploads/2023/12/tire-patched-300x224.png)