Are you having trouble getting your car to start?

Does it only start when you pump the gas?

If so, you may be dealing with an issue related to your car’s air and fuel mixture.

This article will explore the various parts that can cause this issue, so you can diagnose the problem and take the necessary steps to get your car running again.

We’ll look at the air filter, fuel filter, fuel pump, compression, and throttle body to pinpoint the cause of the problem.

By the end, you’ll have the knowledge you need to get your car back on the road. – Or know what a auto technician will be checking for you.

Possible Causes of the Issue

The engine’s stalling when starting might be due to a clogged air filter, faulty fuel filter, worn fuel pump, low compression, or a faulty throttle position sensor – all of which could impede its ability to roar to life.

To identify the cause, it’s important to check the spark plugs, replace the air filter, check the fuel tank, inspect the hoses, and test the battery.

Additionally, the fuel filter should be checked for any signs of dirt or blockage. If it’s clogged, then it must be replaced. They are cheap, so there is little point in cleaning them.

The air induction system should also be inspected for any cracks or leaks and tested using starting fluid.

Also, the fuel pump should be tested with an amp clamp and compared to the manufacturer’s specifications.

Finally, a compression tester should be used to measure the compression value in the cylinders, and the throttle position sensor should be checked with a DMM.

How to Diagnose the Problem

To diagnose the cause of your car’s starting issue, check the air and fuel systems to see if they’re functioning properly.

Take a look at the air filter, fuel filter, fuel pump, compression, and throttle body to get to the bottom of the issue.

Start by checking the air filter to make sure it isn’t filled with debris that could prevent enough air from entering the combustion cylinder. Then, inspect the air induction system for any cracks or leaks.

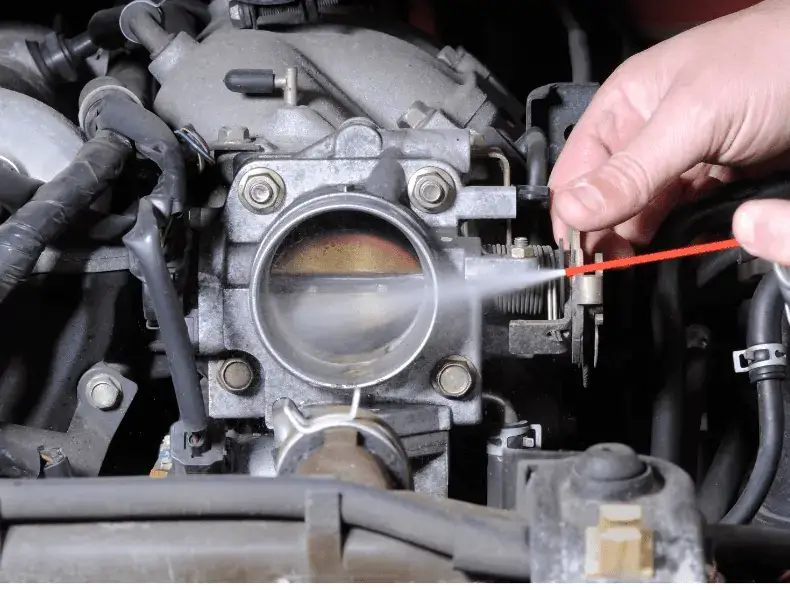

Test for leaks by spraying starting fluid near the suspected area and listening for a change in the engine’s sound.

Next, inspect the fuel filter and the outside condition of the fuel pump. If the fuel filter has a window, check the inside. If it’s dark, clogged up, or dirty, replace it.

For the fuel pump, use an amp clamp to measure the amperage reading and compare it to the manufacturer’s specifications. If the reading is high, the fuel pump needs to be replaced.

Lastly, use a compression tester to test the compression levels. If there is a difference of 40psi between two adjacent cylinders, then the compression value is low.

To check the throttle body, use a DMM to measure resistance. If the digital reading increases or decreases suddenly, this indicates a bad throttle position sensor.

Testing the Ignition System

Test your car’s ignition system by using a spark plug tester – it’s like a litmus test for your engine.

First, inspect the spark plugs for any signs of corrosion or wear. If you can’t see anything, you can use a spark plug tester to ensure the function of the plug properly.

Next, inspect the distributor for any loose or damaged parts. If you find any, you’ll need to replace them. Also, check the spark timing to make sure it is set correctly. If it’s off, you can adjust it by using the manufacturer’s specifications.

Finally, check the alternator and the ignition coil. If the battery isn’t charging, you can use the voltmeter to check the output of the alternator.

If the alternator isn’t producing enough voltage, you’ll need to replace it. Also, use an ohmmeter to check the resistance of the ignition coil. If it’s too low, you should replace it.

By thoroughly testing each part of your ignition system, you can find and fix the cause of the problem.

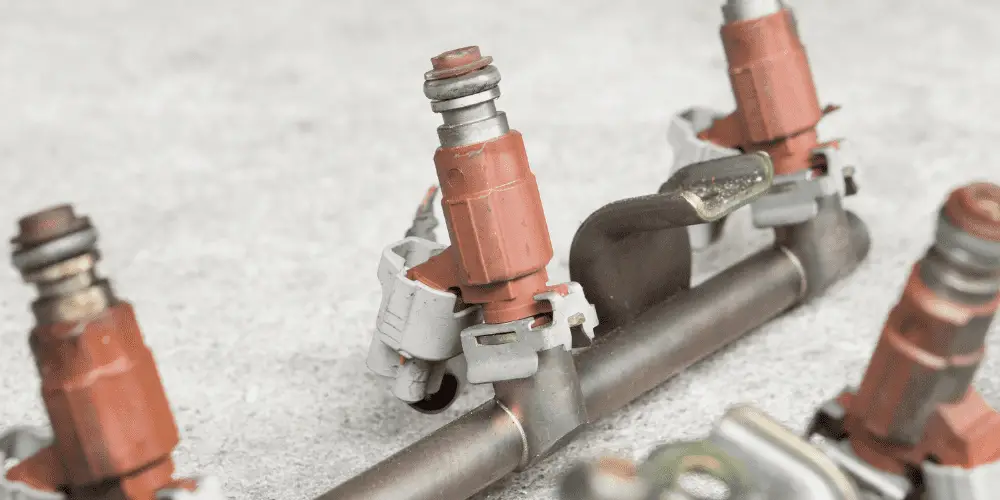

Cleaning the Fuel Injectors

Cleaning your fuel injectors can help ensure your engine runs smoothly and efficiently. To do this, you need to use the right cleaning tools, such as a fuel injector cleaning kit. Depending on the type of fuel injectors you have, the kit you need may vary.

If you have a multi-port fuel injection (MPFI) system, you need a pressure-based cleaning kit, while a single-point fuel injection (SPFI) system requires a vacuum-based cleaning kit.

In addition to using the right tools, you also need to maintain your fuel injectors by checking the ignition timing and fuel pressure. This will help ensure the fuel injectors are working properly and that the air and fuel mixture is correct.

Finally, cleaning your fuel injectors regularly is important to prevent clogging or build-up. This can help you avoid costly repairs and allow your car to start quickly and reliably.

Checking the Fuel Pump Pressure

Checking the fuel pump pressure is essential for keeping your engine running smoothly, so make sure you do it regularly!

You’ll need an amp clamp and a voltmeter to check the fuel pump pressure. First, place the amp clamp over the positive pump wire and use the voltmeter to set and record the amperage reading.

Compare this reading to the manufacturer’s specifications. If the reading is higher than the manufacturer’s specifications, the fuel pump is working harder and needs to be replaced or serviced.

You should also check the spark plugs, inspect the carburetor – on older cars, inspect the air intake, replace the fuel filter, and check the vacuum lines for any cracks or leaks.

All of these components can cause a decrease in fuel pump pressure, so it’s important to make sure they’re in good condition.

Replacing the Fuel Filter

Replacing your fuel filter regularly is a crucial step in keeping your engine running smoothly, and it can make all the difference in how your engine operates.

It’s like the difference between an Olympic sprinter and a tired, old man struggling to keep up! It’s a cheap piece of kit that can make a world of difference.

Before replacing the filter, examining the clogs, blockage, and hoses for any dirt or debris is important. Once the filter is removed, the fuel pump should be tested to ensure it’s functioning properly.

Once the pump is tested, the nozzles should be cleaned and the filter replaced. Make sure to attach the filter securely in place, as a loose filter can cause the engine not to start.

Double-checking the filter can easily avoid this before turning the engine on.

Testing the Fuel Pressure Regulator

Now that you’ve replaced the fuel filter, it’s time to test the fuel pressure regulator. This component is responsible for regulating the amount of fuel that enters the combustion chamber.

A faulty fuel pressure regulator can cause problems with cold starting, engine performance, and idle speed.

You’ll need a fuel pressure test kit, an oxygen sensor, and a fuel injector tester to test the fuel pressure regulator. Start by connecting the fuel pressure test kit to the fuel system.

Then, connect the oxygen sensor to the fuel injector tester and start the engine.

If the fuel pressure reading is lower than the manufacturer’s specification, then the fuel pressure regulator needs to be replaced.

Conclusion

There are several components that could be causing the issue, but with a bit of knowledge and patience, you can troubleshoot and find the underlying cause.

It’s like a puzzle—all the pieces have to fit together for the engine to start.