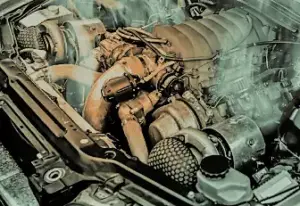

Cars make all sorts of noises, but nothing is more unsettling than a whining, noisy alternator. If the alternator goes bad, the battery won’t be able to provide power to anything in the vehicle. Furthermore, the problem worsens as you accelerate.

Alternators make noises when accelerating due to loose or worn bearings, drive belts, and broken pulleys. The noise gets louder when you accelerate because the pulley pulls the belt over the bearings, causing the parts to squeak.

Throughout this article, you’ll discover why your alternator is making strange noises when you accelerate, what you can do about it, and how to prevent it from happening down the road.

What Causes Alternator Noises When Accelerating?

Alternators make noises when accelerating if they have loose, rusted, or missing components. The bearings, belts, and other parts are designed to stabilize and control the alternator, ensuring that it supplies power to the battery. If the alternator fails, the battery won’t charge, and your car eventually won’t start.

Here’s a deeper look into the primary reasons your alternator is making noises while accelerating:

- The bearings are loose. Loose bearings are the most common explanation for an alternator that makes strange sounds. The bearings roll with the belt, preventing it from getting stuck. However, rusted and old bearings don’t move as quickly as the metal-on-metal friction loosens them, causing unwanted noises.

- There’s rust in the alternator assembly. Alternators are prone to rust if you live in a high salinity area. For example, coastal cities have a higher chance of rusting car parts. Heavy rainstorms can also cause rust in the alternator. If this happens, your alternator will screech and squeal.

- There could be a loose screw. Alternators have mounting bolts that prevent them from sliding around or falling off the tracks. Loose nuts and bolts will make the alternator rattle, especially when accelerating. The more you drive, the looser the bolts will get, and the louder the sounds will be.

- The belt is worn and needs to be replaced. The drive belt goes through all of the vehicle’s pulleys to provide power. If the belt is damaged, loose, or worn, it’ll squeak and screech. These sounds get progressively louder when you accelerate, especially if you get on the highway.

- The alternator pulley system is loose or corroded. According to Car Cody, loose pulleys can cause squeaky noises that make car owners think it’s the belt. Truthfully, your vehicle’s drive belt might be in good shape, but you won’t be able to tell if the pulley is loose or off its track.

If any of these issues affect your alternator, they must be addressed as quickly as possible. Alternator problems impact every part of your vehicle since none of them will work without adequate power.

Fortunately, we’ve compiled a list of solutions in the following section for you that could get your alternator back to its original condition.

How to Fix Accelerating Alternator Noises

To fix accelerating alternator noises, follow these steps:

- Replace the worn alternator bearings. Most car alternators have two ball bearings. We suggest replacing both of them if one is worn or damaged. They often fall apart, so getting one and not the other is no use. Turn off the car, disconnect the alternator, and pull off the front bolt to reveal the bearings.

- Get a new drive belt for the vehicle. Drive belts are quite complex. It’s best to hire a professional if you’ve never replaced a belt in your car. Check your vehicle’s blueprints or diagrams to know how the drive belt needs to be aligned. Replacing the belt will improve everything in the pulley system.

- Tighten the nuts and bolts around the alternator. Use a socket wrench to secure everything. This step could prevent you from having to replace the whole alternator. Often, loose screws are the sole reason your car makes unexpected noises when you drive around town.

- Replace or tighten the pulley. These pulleys can be loosened and replaced by adjusting their bolts. Keep in mind that removing the pulley will loosen the belt, causing it to fall off the remaining pulleys. You’ll have to redo the drive belt. Again, it might be best to hire an expert if needed.

- Lubricate the bearings. Use liquid bearing oil. Place a few drops of the oil on each alternator bearing, then immediately drive the vehicle. Driving the car will mix the lubricant over all balls within the bearing. This can also be used as a preventative step to keep your alternator’s bearings operating as they should

These suggestions might be a bit pricey, but tackling them before they ruin your battery or throw the drive belt off the pulley system is better. Without a drive belt, your vehicle will overheat and fail to function properly. Furthermore, you’ll have to replace several components rather than just the alternator or a bearing.

Preventative Maintenance for Alternators

Preventative maintenance for alternators includes lubricating the bearings, oiling the pulleys, replacing the belts as needed, and keeping the battery charged. Another helpful tip is to drive the vehicle at least once per week. This will ensure the alternator has time to charge the battery as needed.

Lubricating various components around the alternator and tightening all loose bolts can save you hundreds of dollars. A small bottle of bearing oil costs about $300 to $400 less than a brand-new alternator replacement from most mechanic shops. It also prevents other parts of the pulley system from rusting.

Final Thoughts

The alternator is an irreplaceable part of your vehicle. It must be checked, monitored, and repaired as soon as possible if it’s making unusual sounds especially when accelerating. Letting the alternator go bad for too long can damage the battery.